Printed Electronics & HMI Products

CCL Design manufactures value added assemblies, combining state-of-the-art multi-layer human interface technology (HMI), through highly decorated interfaces with electronic functionality all in one unit.

Products

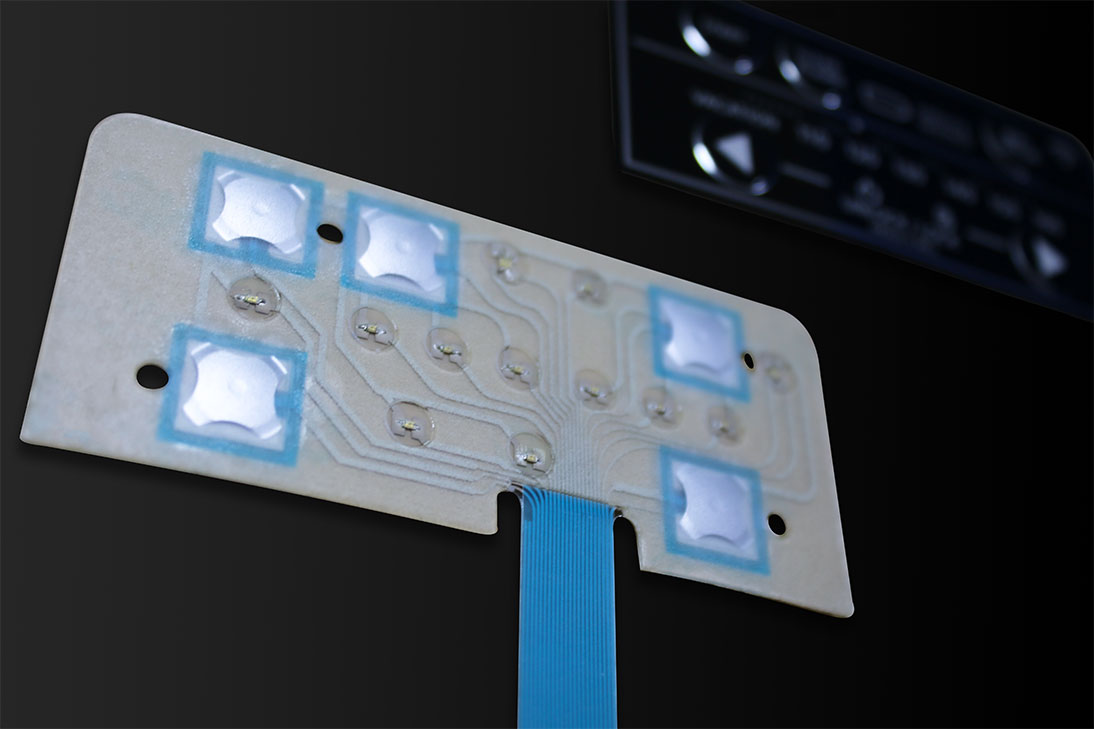

- Decorated overlays are assembled on printed electronic parts with printed tracks, metal switches and LEDs

- Enhanced decoration is carried out using UV moulding, sputter coating (NCVM) and screen printing

- Typical substrates are polyester and polycarbonate

- Chemical-resistant, anti-microbial and UV-resistant materials

- Multiple embossing options (indluding 3D effects)

- Backlighting

- Integrated with flexible circuits and PCB technology

- Tactile and non-tactile response keys

Membrane Switches and Control Panels

- Thin, flexible, lightweight constructions

- Simple fabrication

- Cost-effective solutions

- Solvent, UV and water-based ink options

- Highly conductive silver inks

Screen Printed Circuitry & Printed Electronics

- Thin, flexible constructions

- Excellent first touch sensitivity

- Large dynamic range

- Mechanical reliability

- Meets international durability and environmental standards

- Sensitive with fingers, gloves, passive stylus and in wet environments

- Works with various surfaces, displays and sensors

- Works behind plastics, glass, metal, leather, wood, fabrics, etc.

- Integrates with next generation feedback systems (Haptics)

Force Touch

- Hardcoated substrates with excellent scratch resistance and anti-fingerprint coatings

- Single-layer constructions - thin and lightweight with good first touch sensitivity

- Decoration, printed circuitry and electronics components are all subsurface making the product completely indelible

- Ideal for in-mould electronics (IME)

- Enhanced decoration carried out via screen printing, UV moulding and sputter coating

Capacitive Touch

- Decorated overlays and are assembled on printed electronic track layers incorporating selected interface technology and LEDs

- Enhanced decoration is carried out using UV moulding, sputter coating (NCVM) and a selection of advanced printing technologies.

- Typical substrates are polyester, polycarbonate, PMMA, glass and fibre reinforced products

- Thin and soft touch surfaces to thick high gloss

- Chemical-resistant, anti-microbial and UV-resistant materials

- Multiple embossing and in-mould options (including 3D effects)

- Backlighting

- Integrated with flexible circuits and PCB technology

- Tactile, non-tactile, haptic, force and proximity response keys

- IP ratings to meet customer needs

Human Machine Interface Assemblies

Technology

- Allows for fine detail reproduction, together with accurate colour matching and consistent repeatability

- Used for high-impact surface or subsurface decoration on a variety of substrates

- Offers flexibility with ink systems (UV-based, water-based, solvent-based)

- Ink finishes include metallic, mirrored, colour shift, reflective and functional pigments

- Unlimited number of print passes and colour changes with high levels of opacity

- Allows for printing onto thicker substrates - up to 5mm thick

Screen Printing

- Ideal for high volume and fast assembly

- High-speed, precise electronic component assembly

Electronic Component Pick and Place

CCL Design specialises in Printed Electronics & Human Machine Interface Products. We have market-leading capabilities, including the very latest pick and place technology.

- UV moulding

- Sputter coating

- Non-conductive vacuum metallisation (NCVM)

- Thermoforming

- Embossing

Decorative Techniques

Printed electronics products by CCL are enhanced using a wide range of decorative techniques. Used in conjunction with digital printing and screen printing, these include:

Cleanroom Manufacturing

CCL Design manufacturing sites are world-class, and our operating environments are controlled to the highest standards in the industry.

Products are manufactured in class 10K and 1K cleanrooms.