Functional Materials & Die-Cuts

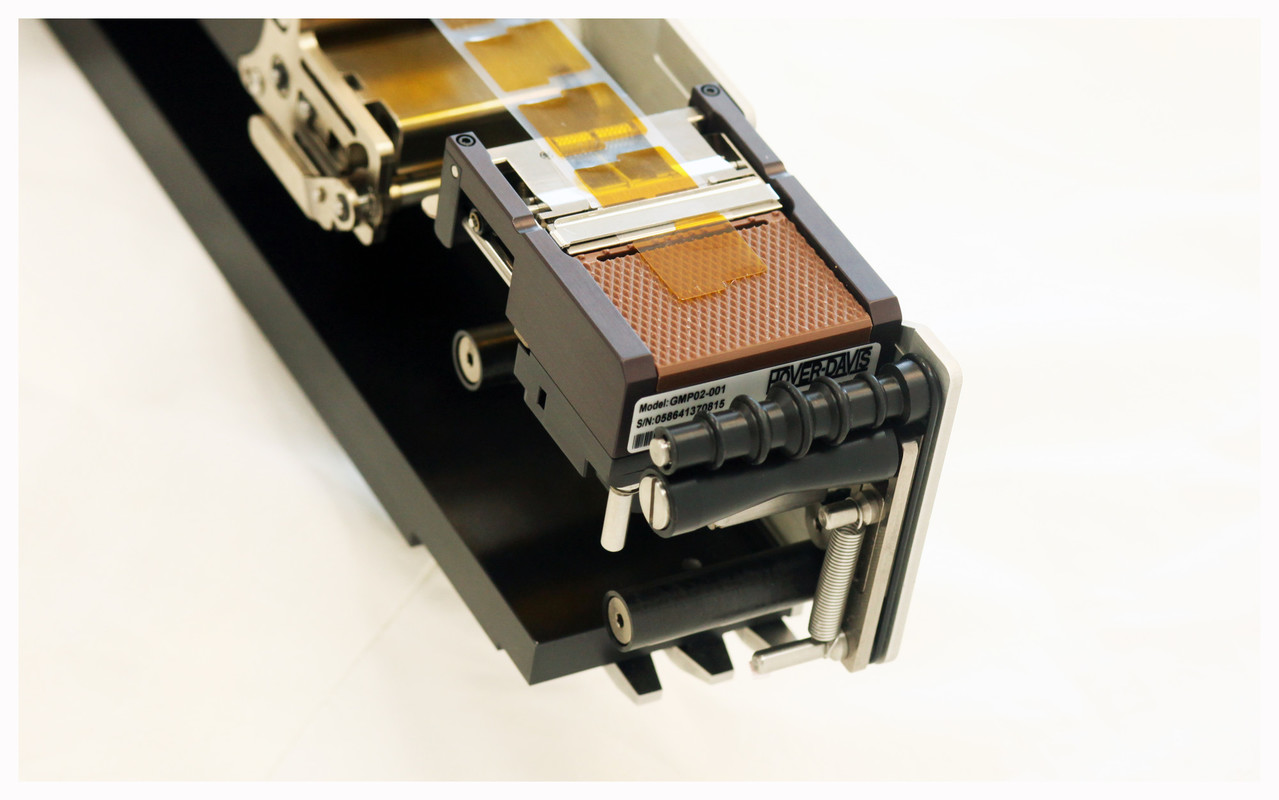

CCL Design manufactures die-cut and functional components for use in electronics, automotive and industrial applications. Our multi-layer constructions enable applications with multiple components, allowing for more cost-effective device assembly and BOM management streamlining.

Die-Cut Product Ranges

- Acoustic gaskets

- Main lens and LCD screen gaskets

- Bumpers, cushions, spacers and gap fillers

- Environmental sealing

- Thermally and / or electrically insulating seals for optimal electronic device performance

Gaskets, Seals and Bonding Solutions

- Thermally conductive adhesives and tapes

- Thermal interface materials (gap and sil pads)

- Electrically insulative thermal materials

- Phase change materials

- Graphite thermal spreaders

Thermal Management

- Conductive materials

- Electrical insulators

- Dielectrics

- EMI absorption

- RFI shielding

- ESD (electro-static dissipation)

Electrical Management

- Dampening - vibration and airflow noise reduction

- Shock absorption

- Acoustic transmission - gaskets, mesh and grills

Acoustic and Vibration Management

- Thin, functional films - optically clear or decorated

- Optically clear adhesive (OCA) custom solutions, requiring advanced conversion

- Protective liners with custom adhesion strength and clean removal

- Adhesives that bond to a wide variety of substrates

- Superior protection against dust, water, heat, oil, chemicals, mould and harsh environments

- Features include anti-glare, anti-reflection, anti-scratch, anti-fingerprint and UV resistance

- Cleanroom manufactured for ultimate optical purity

Display Lens, Bonding and Protection

Rotary Die-Cutting

The latest in rotary press technology

The most precise machines on the market

CCD camera registration and inline CQC systems

Advanced material utilisation for high waste designs

Island placement

Minimal operator intervention required

Less manual work required for complex parts

Allows for the production of complex, multi-layered products in a single pass

Flatbed Die-Cutting

- Cost-effective, highly precise, low to mid volume semi-rotary manufacturing lines

- Fast tooling availability - often within 24 hours

- Suitable for thicker materials

- Modular to fit application and production needs

- Tight tolerances due to a specialised registration system

- Highly effective for all phases of manufacturing, from prototyping and NPI to mass production

Automation

As the need for highly complex precision components increases, so manufacturing process must evolve. At CCL Design, we have invested in the very latest auto-inspection and auto-assembly technologies.

Not only are we focusing on increasing speed and accuracy, but we are also optimising costs and eliminating unnecessary waste within manufacturing processes.

Die-Cut Materials

The quality and performance of CCL Design die-cut products is driven by state-of-the-art processes, combining a wide range of functional materials.

From common application die-cuts to complex multi-layer constructions, materials are key to performance.

- High-performance foams

- Films, tapes and mesh

- Fabric and metal foils

- Optically clear adhesives

- Thermal management materials

- Conductive fabrics, foams and thin metals

- Printable materials - allowing for logos, instructions and information

- Materials with UL and NEMA flame retardant ratings

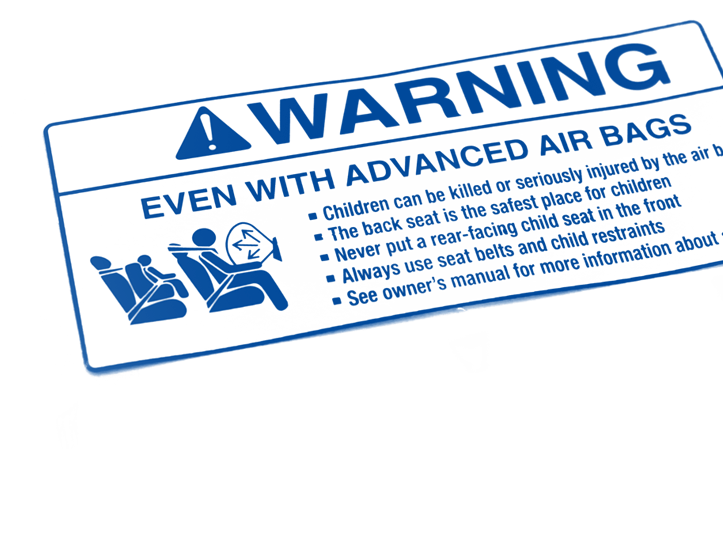

Airbag Safety Products

CCL Design airbag safety products are used globally for the protection and packaging of airbag security systems.

Airbag safety labels

Airbag covers

Airbag curtain wraps

Tyvek tapes for airbags

Flame-retardant coated materials

Case Study

Next-Gen Control: How CCL Design Helped a Motor Control Giant Navigate Challenging Times

A global leader in motor control systems faced a perfect storm: unfavourable market conditions, component shortages, and escalating supply chain costs. They turned to CCL Design for a solution.

Read more