Decorative Products

Branding products by CCL Design are manufactured using a combination of state-of-the-art processes. These can be layered in any order, to deliver an incredibly diverse range of high quality looks and surface finishes.

Branding Product Ranges

- Fully Customisable Surface finish to meet design needs, eg. SPI mould finish textures, soft touch, selective patterns, incorporated logos etc.

- Base material can be clear, allowing for the inclusion of windows and/or Secret Until Lit features

- Excellent abrasion and chemical resistance

- Supplied as sub-assembly for easy final assembly

- A cost-effective solution with inherent flexibility, delivering higher process yields than alternative (metal) solutions

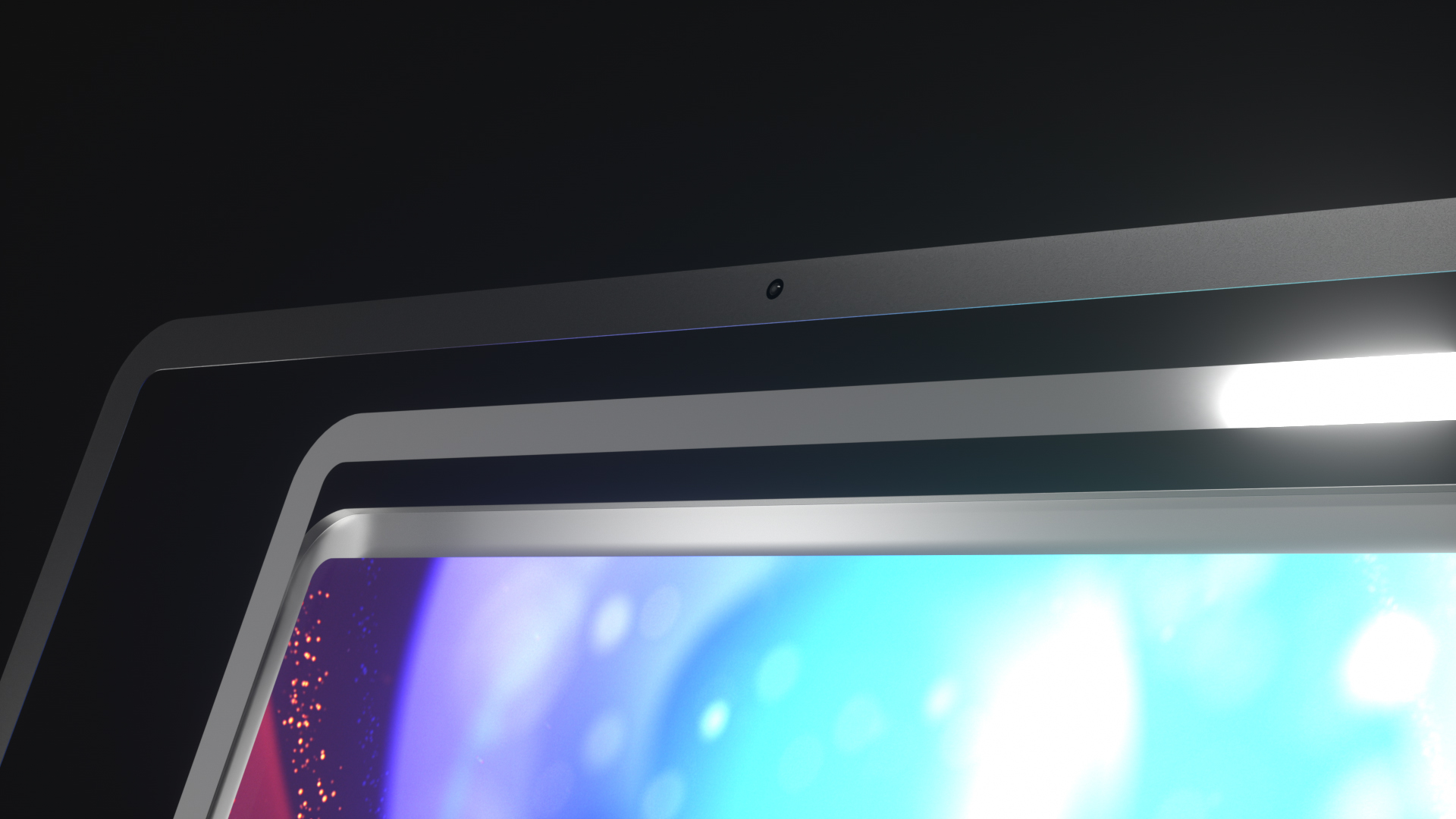

Notebook and LCD Display Bezels

- Clear plastic base film allows for backlighting

- Backlighting allows for features to be hidden until you want them displayed - genuine deadfront

- Features can be coloured to match requirements

- RGB lighting with specially printed features can be used to display variable icons in essentially the same position

- This provides the flexibility of decoration and coating processes in combination with the most suitable clear film thicknesses and chemistry, delivering high quality cosmetic and functional features

Secret Until Lit Features

- Engineered light guides reduce product thickness, while delivering uniform backlighting

- Colour changing features

- Can be supplied as an assembly, including LED and connector/controller

- Process flexibility allows these features to be incorporated into almost any product geometry

Backlit Logos

- Decorated panels which deliver required durability, functionality and cosmetics

- Available in hard-coated films, composites, or etched glass substrates

- Thickness to suit the application

- Durable decoration ensures long lasting appearance

- Surface textures through UV moulding or etch processes

- Anti-Fingerprint and other functional coatings through spray, or PVD

Touch Interfaces

- Surface or sub-surface decoration and patterning

- Glass, Plastic, or Composite materials

- Thickness to suit the application

- Durable decoration ensures long lasting appearance

- Surface textures through UV moulding or etch processes

- Anti-Fingerprint and other functional coatings through spray, or PVD

Decorative Panels

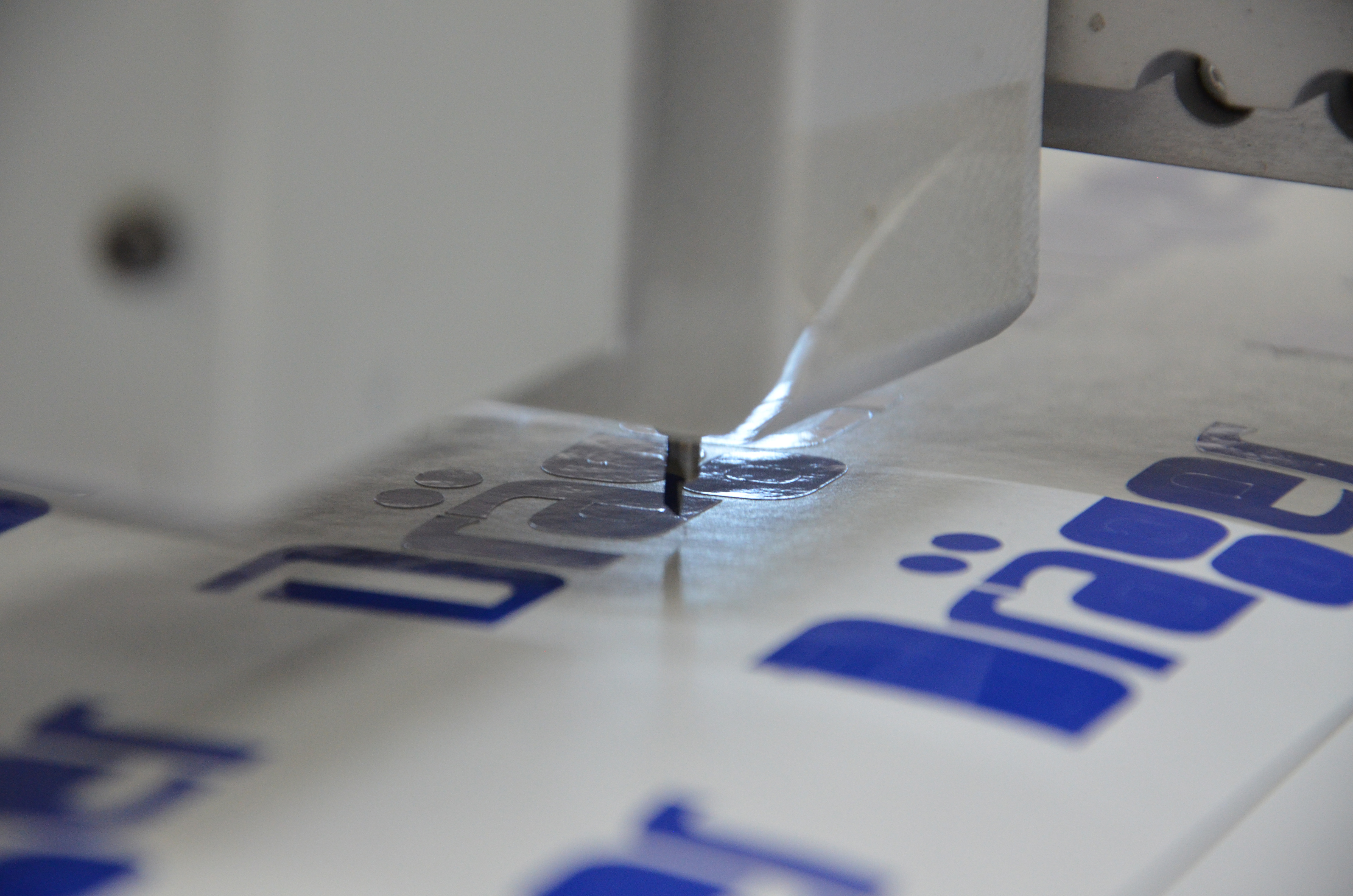

- Films can be cut according to your design

- Waste elements are removed in lettering (e.x. ,,b, a, o")

- Easy handling - using an application tape to transfer

- Exact positioning with an application tape

- Multi-colored printing is possible

- Different materials are available (plastic & metal for example)

Foil lettering for marking your products individually

- Labeling of machines and valuable products

- Advertising labels

Application area;

Screen Printing

- Allows for fine detail reproduction, together with accurate colour matching and consistent repeatability

- Used for high-impact surface and sub-surface decoration on a variety of substrates - mainly glass and plastic

- Ink systems used include UV-based, water-based and solvent-based

- Produces a wide range of ink finishes, including mirrored, metallic, reflective, colour shift and functional pigments

- No limit to the number of print passes and colour changes

- Ideal for printing on thick substrates

Class Leading Treadplate Technology

CCL Design in Haian, Solingen, Munich, Guanajuato offer a range of treadplate options including features such as;

- Aluminium

- Stainless Steel

- Backlit

- PU Resin-Coated

- Foiled

- Plastic

Surface Decoration

- Used to create raised features – either discrete images, or wallpaper patterned surface textures

- Can deliver 3D effects when combined with specific tooling and coating techniques

- Superior tooling allows for very fine, consistent textures and clean transition between features

- First surface application offers a tactile experience with increased abrasion resistance

- Second surface application enables a multitude of cosmetic effects

Thin Films and Optical Coatings

- Decorative vacuum metallisation (VM) and non-conductive vacuum metallisation (NCVM) enhance cosmetic effects

- Anti-reflection coatings reduce light lost through reflection and increase transmission across the visible spectrum

- Additional functional coatings include anti-fingerprint, easy-clean and super hard coatings

Decorative Films: Design and Manufacturing Capabilities

In-house R&D providing seamles transition to manufacture

Rotogravure printing - solvent and water-based

Conversion of films to specific lengths and sizes

Topcoat formulation

Compounding of topcoats and intermediate

State-of-the-art lab testing capabilities

Architectural Products: Graphicolor Film Technology

Functional and decorative films for vinyl siding, decking / railing and window profiles

Topcaps for vinyl siding provide a decorative wood grain or solid colour appearance

Decorative enhancement for vinyl window lineals and plastic composite decking

The most durable exterior films in the industry, using Kynar® 500 paint chemistry and mixed metal oxide pigment technology

Extremely stable UV colour formation that withstands years of outdoor exposure - 30+ years of colour retention and fade data showing a DE change of less than 2.0

Precision Engineering Lights the Way with our Laptop Branding Design

A prime example of our innovative approach is our development of a cost-effective ultra-thin, Backlit Brand Logo Assembly solution for a leading laptop manufacturer.

Read more